Honeywell are responsible for the operation and maintenance of buildings for blue-chip companies.

The ACB Problem

During routine maintenance of the High Voltage and Low Voltage systems of one of their clients in Birmingham City Centre, ExEllison Switchgear Services discovered a problem with the 11000V isolator close-coupled to the Package Substation transformer.

Whilst the problem was temporarily overcome to ensure that power was returned to the building a solution for the long-term integrity of the supply was required.

The unit in question was of an obsolete design so spares were no longer available. Following consultation with ExEllison Switchgear Services Ltd a solution was devised to meet their specific circumstances.

The ACB Solution

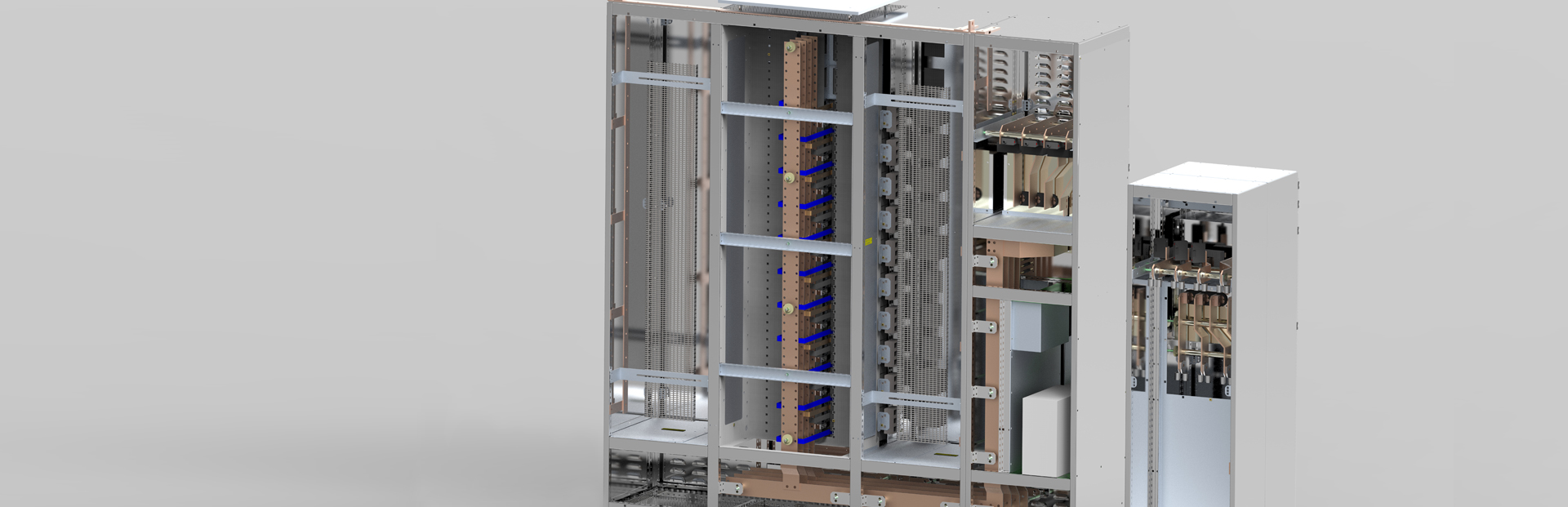

It was agreed that a readily available ACB of standard design be utilised as a replacement for the faulty ACB. With our knowledge of the Ellison equipment we were able to design the interface to enable simple replacement during a single 10 hour shutdown. All of the materials were custom built in advance of the agreed shutdown.

ExEllison Switchgear Services Ltd utilises the latest 3D solid modelling CAD systems to design its products to ensure a first-time fit every time. We have developed standard arrangements for a wide variety of Switchgear retrofits.

In this case a Schneider MV isolator was utilised in conjunction with our custom designed interface.The interface was designed to allow installation into the existing panel with the minimum of modification and down-time. A full assembly kit was supplied with no need for cutting and carving of parts to suit on site.

Only the experience ExEllison have can guarantee a first-time fit without the need for a shutdown in advance of the installation.

CASE STUDY HONEYWELL:

- ACB Replacement Protection replacement,

- Spares

- Switchboard modifications

- Extension Panels

- Emergency response

- Retrofit metering

- Control panels

- Maintenance Installation Services

- Transformer replacement and Substation equipment

Further complications were introduced by the fact that the substation was located on the 7th floor of the building with the lift only reaching the 6th floor.

Specialist lifting equipment was employed to ensure safe movement of the 300Kg isolator.

Specialist High Voltage Engineers ensured the correct termination of the 11kV cabling followed by thorough testing of the modified system before re-energisation.