If you are not replacing the main isolating contacts then you are only doing half a job. All of the power passes through these contacts – are you prepared to continue to use aged contacts the contact pressure of which is produced by aged springs. In our opinion any ACB replacement MUST replace these old components – see separate sheet for full explanation.

We offer the following ACB Manufacturers: ABB, Schneider, Mitsubishi, Siemens, Terasaki, Eaton. If you have another preference we will design a solution for you.

If the proposed retrofit uses a refurbished old Air Circuit Breaker chassis then you are relying on aged worn components. Availability is limited and spares difficult to obtain. We replace the whole ACB. Fixed and moving portions.

Some retrofits utilise old mechanisms to insert and withdraw the retrofit. This has consequences with interlocking between the Air Circuit Breaker and chassis such that the ACB must be off before inserting or withdrawing. Castell locks or other devices are required which may complicate the operation of the device – very confusing in a shutdown / emergency situation. Old mechanisms are prone to jamming / seizing. We replace every part of the old ACB.

Plug-in retrofits can not provide a true 4-pole ACB. Instead you may find a separate solenoid operated contact is used. This introduces major reliability and timing issues to the fourth pole and the Air Circuit Breaker open/closed indicator is NOT mechanically connected to the 4th pole! In our opinion this is totally unacceptable and should be rejected. Where 4-pole ACBs are required, we use true 4-pole Air Circuit Breakers with no complications. We retain all of the standard interlocking and indication without modification.

We always include a new set of CTs within our new retrofit assembly. These are used for the new multifunction metering as well as Power Factor Correction reference. We have found on a number of occasions that a customer looses his PFC because a shoddy ACB retrofit has been carried out and the PFC reference CT has been removed. We include any PFC CT and pick up the loom wiring to ensure your PFC continues to operate.

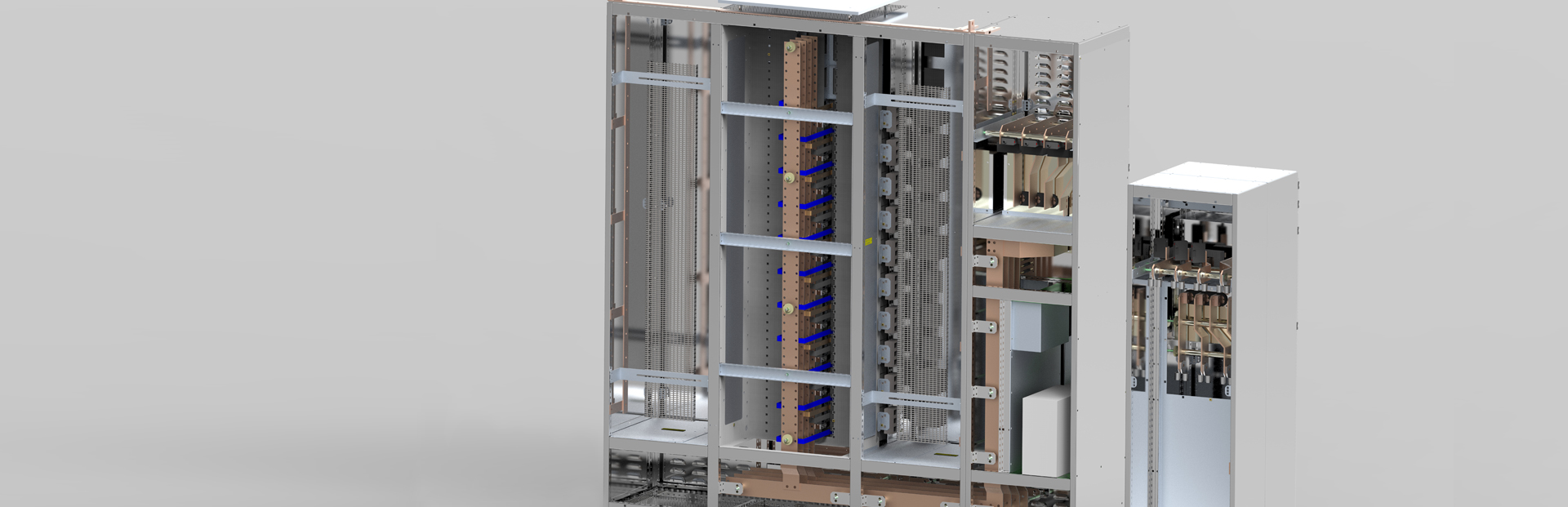

We fit new backup fuses directly to our own copperwork. This allows our new assembly to be completely self-contained. We can then fully benchtest the whole assembly including all control signals and metering prior to delivery. Witness testing at our factory is always encouraged.

We fit metering as standard as part of our selfcontained assembly. We use Socomec, Schneider and Rayleigh Instruments as standard but you may specify your own preference.

Our assembly includes wiring from the new ACB to a set of terminals that pick up the existing standard wiring loom. Any existing control scheme will continue to operate correctly. We can of course offer a complete control scheme overhaul if required.

We utilise completely standard off the shelf Air Circuit Breaker in our retrofit. They are not modified in any way. Therefore you can obtain spares or replacements simply yourselves. A plug-in retrofit may require mounting on old chassis etc. before they can be used. This is difficult and timeconsuming and may result in you having to resort to the retrofit supplier for any future spares requirements limiting your future options.

Do you have to strip down your assembly to access the accessories? Again, we use a standard ACB unmodified in any way. Accessories are fully accessible.

Because we use standard unmodified Air Circuit Breakers, maintenance remains simple. No additional knowledge other than the usual skills required for ACB servicing is required. All parts remain accessible and the ACB is fully removable for servicing or replacement.

We replace the whole Air Circuit Breaker right back to your busbars. During this process we provide a full survey and clean of the existing busbar system. If you are shutting down to replace your ACBs you should verify that your switchboard is up to the job.